Piacenzameccanica,

skills and optimization

for more than 70 years

We trust in innovation that is useful for production.

What sets us apart is state-of-the-art precision mechanics to always guarantee the best result in advantageous time.

Ours, is optimization 4.0.

Industry 4.0 partners

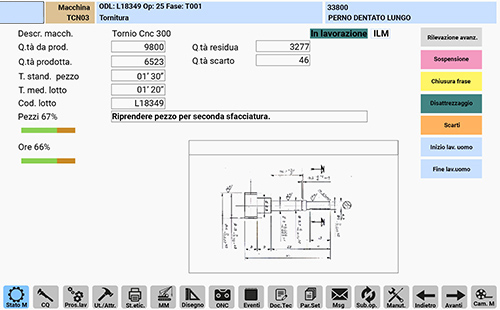

SOFTWARE

ERP

Smart investment. A sound strategy specializing in real-time monitoring of the fruit of each machine: less waste, maximum return.

DIGITAL TOOL

PRESETTER

Technologically advanced autonomous measuring system that can certify accuracy and ensure profitable time savings: machining after machining.

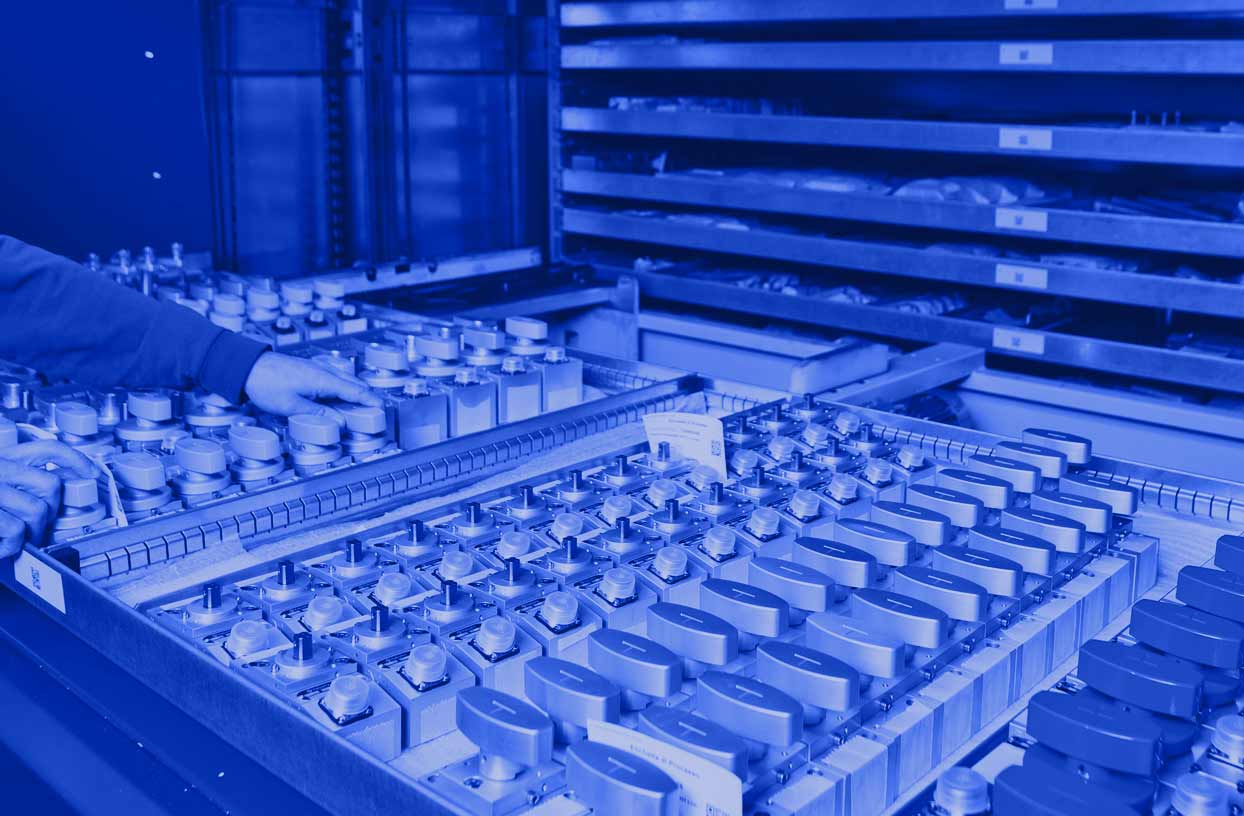

WAREHOUSE

AUTOMATED

The realm ofautomated ordering, where every part to be assembled and finished product is located with logic and rigor for optimal space-time management.

Human commitment,

much more than pride

We conceiveindustry as a living organism. It is the passion, ingenuity and expertise of our people that is the added value, the nerve center of Piacenzameccanica.

Always,

steadfast to tangible values

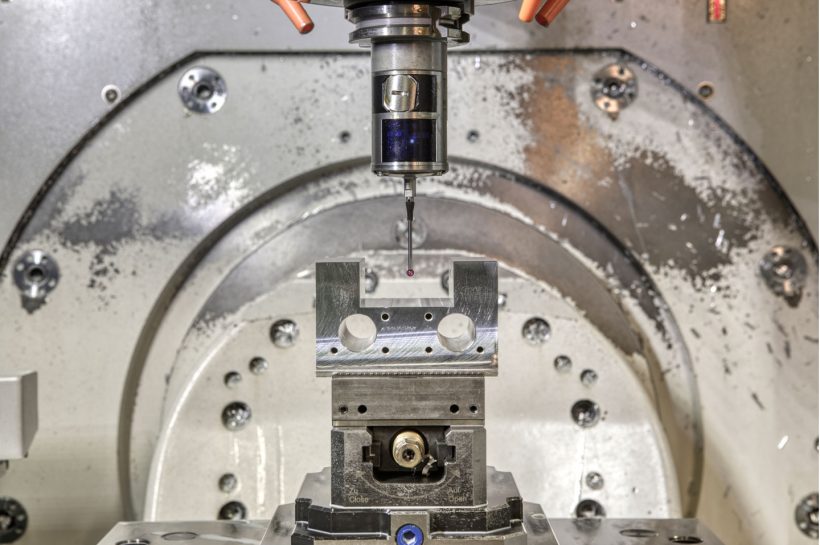

CNC MILLING

The department houses twelve machining centers, most of them five-axis with pallet changers, zero point systems and an internal warehouse capable of storing 120 tools.

Outside is a warehouse capable of holding up to 1,000 tools, already assembled and preset.

5 axes

Vertical

4 Axis Horizontal

CNC TURNING

The department has seven lathes with motorized tooling, Y-axis and counter spindle, capable of completing and guaranteeing complex machining in a single grip. Another four classic lathes are dedicated to the production of prototypes and small series.