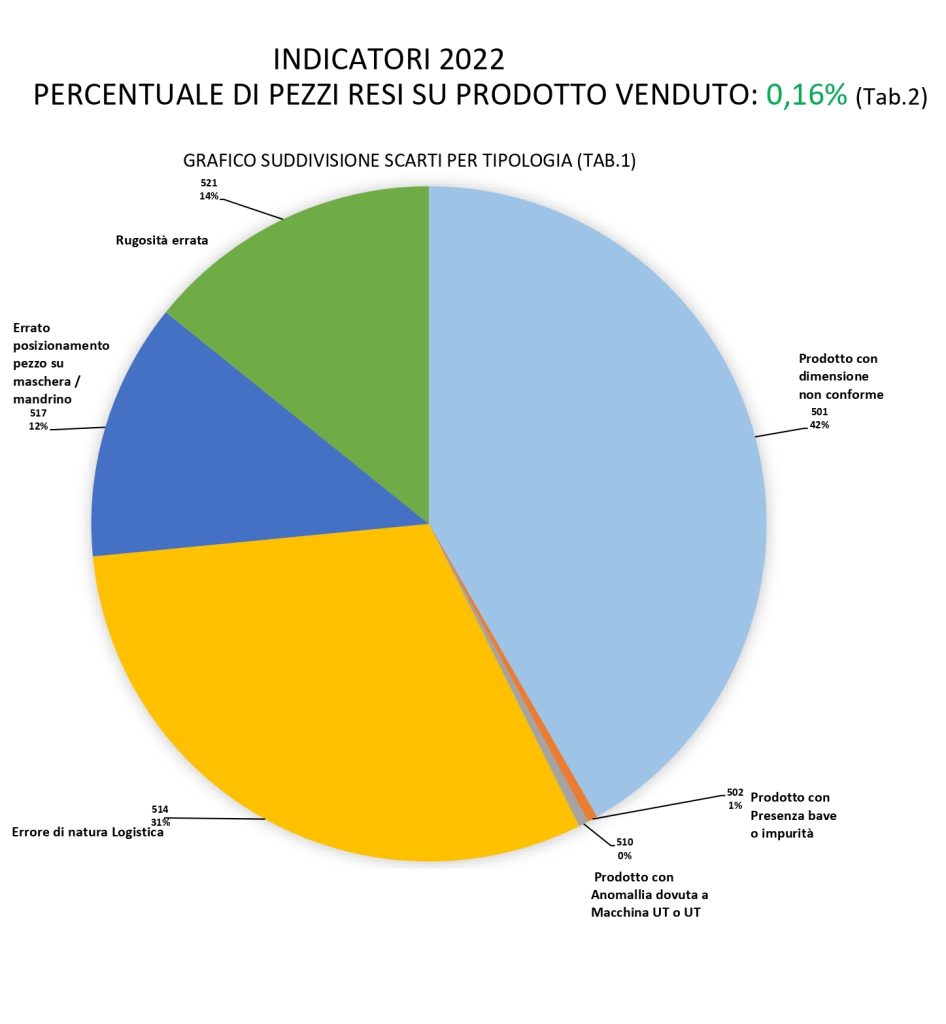

Quality control

In the landscape of companies dealing with precision CNC machining, the management of quality control of manufactured components is treated in different ways, which depend on the internal company vision and the needs of customers. At Piacenzameccanica, we firmly believe that, even when not required, being able to provide certain attestations is essential in order to provide quality service.

Why choose our company

When we begin to analyze the construction of a component, we create what is called a product sheet: contained within it are the characteristics related to the materials needed to build it (type of material, size, weight, etc.) and the processing cycle.

Next, the component to be built is divided into processing stages. The first stage is what is called pick up, which refers to the picking up of the raw component from the warehouse and its transportation to the machine. The next stages, on the other hand, involve CNC machining(milling, turning, etc.).

For each type of machining, a control program is applied, which is managed in a computerized way through tablets on board the machine. The first component to leave the machine is analyzed according to a control diagram, within which the measurements to be taken(dimensional, roughness and other types) are established.

Our components are 100 percent verified: all parts that come out have passed a test, inspection, and assessment incorporated into the processing cycle.

Quality controls are integrated into our system and determined by the ISO certification, which includes a specific way of working and general criteria, as well as customer-specific criteria.

In the railroad industry, where special safety issues must be taken into account, a paper certification is required for each individual component or lot, which must be kept available to the customer for a period of at least 30 years. Everything about the order in question is attested in these documents, whether the information is internal or external to the company. For materials, for example, not only the suppliers are requested, but also certificates with their mechanical properties and chemical composition.

Regardless of requests, our company will process certifications of the materials used and treatments and keep them so that they remain available at all times should the need arise.

Our strength lies in havingcomplete traceability of allprocessing steps and all materials used in the construction of each component-all managed by the company's computer system.

Only in this way can we ensure consistently high quality standards for our customers , continuously improving in terms of efficiency and productivity.