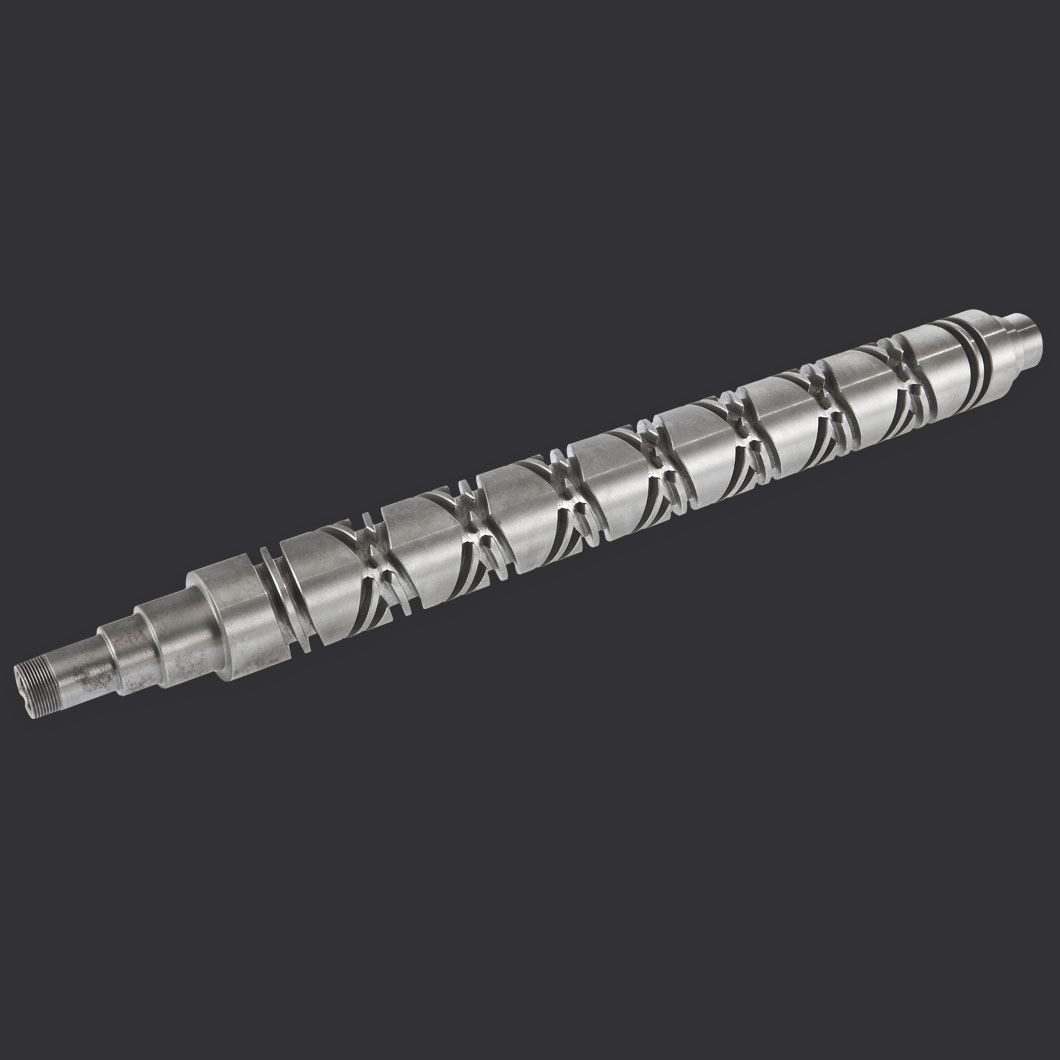

TURNING

CNC

The seven lathes with a Y-axis, motorized tooling and counter spindle that we have at our disposal enable us to carry out elaborate and complex machining in a single grip. Whereas, four other conventional lathes are exclusively dedicated to the production of prototypes and small series.

It is theautomation of our machinery that exponentially increases the company's yield level, zeroing the possibility of error and speeding up the entire production process.

Machine park

Our machines are able to offer performance and competitiveness in all their performance, certifying results from the best value for money on the market. We invest in a future optimized in time and cost, as well as space.

We offer high-performance and competitive solutions, thanks to

an optimization of workingtime and costs at

pace with the most advanced industry technologies

Flexibility, competence and accuracy

Specializing in tailor-made small and medium series production, we offer a functional and personalized service to each of our customers. We design and shape quality mechanical components from miniaturized to more elaborate and intricate machining. We handle all kinds of materials, from aluminum to plastic, but 70 percent of the company's core business focuses on light alloys.

The organization's high level of qualification and the versatility of Piacenzameccanica's in-house CNC machinery enable us to meet the most demanding requirements and collaborate with business sectors ranging from rail to pharmaceutical, aeronautics to automotive.