Machine park: the importance of equipping yourself with the right hardware

How to choose the production technology best suited to one's performance needs? How much and how does the adoption of machinery with certain characteristics impact business profitability? Precision machining operators should be well aware that the equipment that makes up machining centers are not equal and interchangeable, as they are optimized for specific uses. Some machines are great for prototyping, others more suitable for finishing through heat and surface treatments: in general, the elements of the machine fleet determine the quality of the finished product and impact production times; therefore, it is important to equip oneself with state-of-the-art systems that reduce time and costs, limit the risk of accidents and human error as much as possible, and allow for meeting the agreed deadlines for the fulfillment of each job.

Because of this, PiacenzaMeccanica's company policy is aimed at constant and lively updating, an evolutionary growth path oriented towards innovation and aimed at the production of functional mechanical components, with complex design and increasingly sophisticated finishes. For several years now, the company has been structured to be able to offer maximum flexibility and guarantee the management of variable production volumes, ranging from small batches to large quantities, while always ensuring the non-negotiable quality of its manufactured products. Enabling it to offer solutions in step with the most up-to-date requirements of its target sectors are state-of-the-art equipment and machinery.

Despite the artisanal appearance and the family atmosphere in the company, Piacenza Meccanica in fact carries out a structured investment program that disregards the facilities and incentives that are periodically allocated to the industry. On the strength of the knowledge and experience gained in more than half a century of activity in the field of precision mechanics, over the past decade, the company has fully renewed its fleet of machines with the aim of ensuring unparalleled performance and maintaining a strong position in the market.

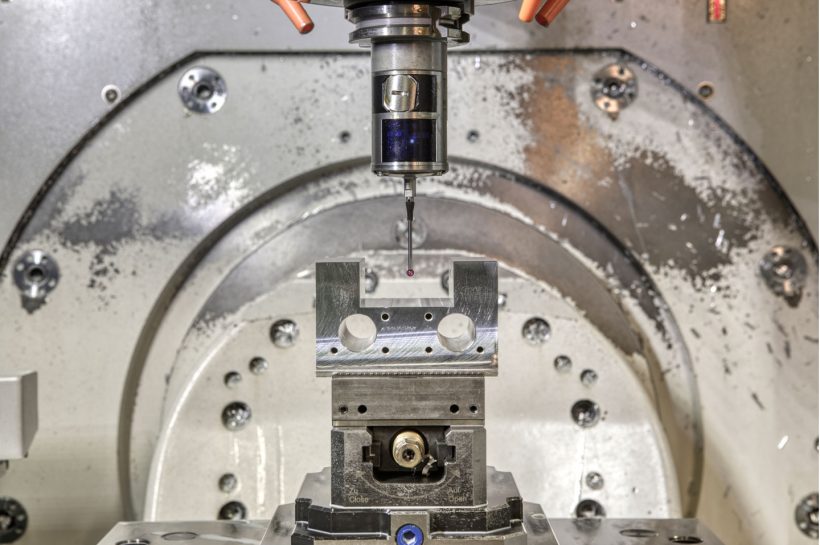

CNC MACHINING CENTERS

Process automation is the main challenge to be faced and overcome for the future. Today it is required to produce large volumes as well as small batches, all quickly and at generally low cost. Without a machine fleet that is up to the task, it would be very difficult to keep up: it is therefore necessary to equip oneself with machinery aimed at optimizing the product value chain and reducing costs, paying attention to increasing integration of the various elements from a functional, energy and diagnostic point of view.

The devices that convinced management in terms of investment solvency and technological reliability bear the name of brands recognized globally as leaders in offering particularly interesting and competitive OEM solutions. These are mainly multi-pallet machines that enable the simultaneous management of different production stages, granting the operator the possibility of alternating finished parts with workpieces without causing downtime. The main advantages of using these machines, can be ascribed to the technologies integrated in them; not only programming languages universally recognized for reliability and performance, and computer management software with tablets on board the machine that manage individual processes and coordinate production as a whole. When we talk about technologies, we mainly refer to the implementation of solutions that manage machine tooling and tool change, and equipment such as modular plates and vices set up to position and anchor the part according to the zero-point system that guarantees micro-millimeter accuracy.

Certain strategies greatly impact both the quality of production and working conditions, greatly facilitating the lives of operators and describing a context in which the resource is not sacrificed to production but is an integral part of it. Training and development, technology and innovation, effectiveness and optimization, transparency and professionalism are in fact the values that inspire and guide PiacenzaMeccanica's mission: to produce mechanical components of the highest precision and unparalleled quality, for progress that is truly at the service of mankind.